Gorilla Hammers, industry leaders since 1938

February 23, 2024

Benefits of Automatic Lubrication

June 25, 2024Pin grabbers and quick couplers for backhoes, mini excavators, and crawler excavators: Making attachment transition easier!

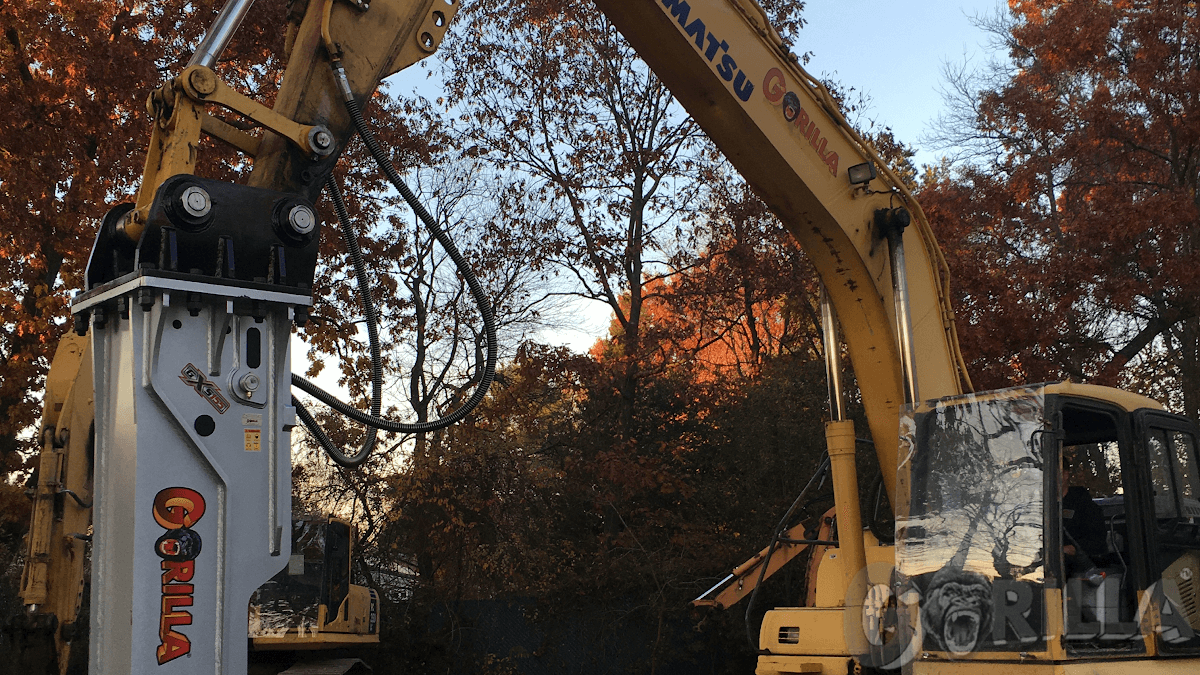

Excavation and demolition contractors are always trying to maximize efficiency. It used to be common for each contractor to have a “hydraulic hammer machine”, “digging machine” and “grapple machine.”. If you wanted to change buckets or switch to a hydraulic breaker, compactor, grapple, or other hydraulic attachment, you had to knock the pins out and then drive them back in after the transition. If you’ve ever done it, it is backbreaking work swinging the largest sledgehammer you have. This frequently takes a second person in the cab to “jiggle’ the controls to line up the stick and link of the excavator or backhoe with the attachment, made worse by what is typically an uneven job site surface. This takes a lot of time and once you start swinging that sledgehammer, it gets even worse resulting in a sore back and shoulder, and often an impact injury from a missed blow. To speed transition and avoid injury, pin grabbers and quick couplers have become the norm, allowing one excavator or backhoe on the job site to perform multiple tasks.

a “hydraulic hammer machine”, “digging machine” and “grapple machine.”. If you wanted to change buckets or switch to a hydraulic breaker, compactor, grapple, or other hydraulic attachment, you had to knock the pins out and then drive them back in after the transition. If you’ve ever done it, it is backbreaking work swinging the largest sledgehammer you have. This frequently takes a second person in the cab to “jiggle’ the controls to line up the stick and link of the excavator or backhoe with the attachment, made worse by what is typically an uneven job site surface. This takes a lot of time and once you start swinging that sledgehammer, it gets even worse resulting in a sore back and shoulder, and often an impact injury from a missed blow. To speed transition and avoid injury, pin grabbers and quick couplers have become the norm, allowing one excavator or backhoe on the job site to perform multiple tasks.

The most common types of pin grabbers and quick couplers are manual and hydraulic:

Manual pin grabbers or quick couplers for attachments:

These are very easy to install, as there are no auxiliary hydraulics required. You simply knock the pins out of your bucket and install the pin grabber in its place. Once in place, you no longer have to drive attachment pins in or out to change buckets or transition to a hydraulic hammer, hydraulic compactor, or any other hydraulic attachment. The disadvantage of a manual pin grabber or manual quick coupler is that the distance between the pin centers must be the same as the millimeter for each attachment or excavating bucket used. A Cat 320 will only accept Cat 320 buckets with the same attachment pin size and center to center. Further, the person performing the attachment transition with a manual pin grabber must exit the excavator and spend a few minutes or backhoe to engage the spring, close the latch, install the pin or tighten the screw that holds the attachment pins in place, and change over/disconnect the hoses if they are utilizing a hydraulically powered attachment. However, excavation and demolition contractors enjoy the much lower cost of purchase, ease of installation, avoidance of additional hydraulic lines, and simple means of closing the coupler on the attachment pins.

Hydraulic pin grabbers or quick couplers for attachments:

These hydraulic pin grabbers are more expensive than manual pin grabbers or quick couplers and typically include a hydraulic kit, which must be installed for operation as they work off of pilot pressure to open and close. However, they do not require the installation of a complete auxiliary hydraulic kit like you would to power a hydraulic breaker, compactor, or other excavator attachment, and the required hydraulic kit can typically be installed within one day with ordinary tools. In short, the hydraulic power supplied to a hydraulic quick coupler applies continual pressure against the pins to hold the attachment in place. Once installed, the pins for buckets and other hydraulic attachments can be grabbed and released via a switch in the cab, leaving the operator only to have to disconnect the hydraulic lines, and on some models spend a few seconds engaging an additional manual catch, wedge, or pin for safe added safetythese hydraulic quick couplers. A further advantage of the hydraulic attachment coupler is that it often has a variance between the pin centers from one-half to around three inches, depending on the brand. This variable pin center tolerance often enables the operator to pick up multiple attachments from multiple brands of backhoes and excavators. For example, many brands of hydraulic pin grabbers in the 20-ton excavator range can pick up both Komatsu and Caterpillar buckets with 80mm pins. As many excavation or demolition contractors use multiple excavator and backhoe makes and models, the use of hydraulic pin grabbers and hydraulic couplers enables them to switch buckets and other hydraulic attachments between them.

Caution: Soft/attachment pins versus stick and link pins.

To allow for wear, most hydraulic and manual pin grabbers and couplers include a set of “soft” pins, which go into the attachment itself. The idea is that as the soft/attachment pins wear against the coupler itself, the pin wears first. The logic behind this is that it is much easier to replace pins than to build up an area where the pin grabber or quick coupler for the excavator or backhoe wore down, Always make sure the soft/attachment pins DO NOT go into the stick and link of the backhoe or excavator during installation, they will become distorted much more quickly than the usual attachments pins and will be very hard to remove if the quick coupler or pin grabber for the excavator is ever removed. We learned that the headway here ONCE around 20 years ago. ONCE!

Whatever your preference or requirements, give Gorilla a call to help guide you as to which type of pin grabber or quick coupler will best fit your needs as you transition between attachments for your backhoe, mini-excavator, and crawler excavator.

Contact the hydraulic hammer experts at Gorilla Hammers today!

Don’t let attachment transitions slow you down! Invest in pin grabbers and quick couplers for your backhoes, mini excavators, and crawler excavators. With these essential tools, you’ll streamline operations, maximize efficiency, and minimize the risk of injury. Whether you opt for manual or hydraulic options, Gorilla has you covered. Contact us at (888) 814-6745 to find the perfect solution for your excavation and demolition needs.