About Gorilla Hydraulic Breakers

Over 80 years of service

Gorilla Hydraulic Breakers began as Tedesco Pump Service, a petroleum service company, in 1938. At that time, the original Joe Tedesco made a living for his wife Rose and three children by traveling throughout the northeast, repairing gas nozzles and the gas pumps’ series of dials measuring fuel output, which he later referred to as “pump computers”.

When Joe passed away suddenly, his eldest son, Joe Tedesco II, was called back from military service at the age of 18 to provide for his mother and two much younger siblings. He continued to provide petroleum services like his father, but expanded operations to include hydraulic and pneumatic repair to serve the industrial, automotive, and utility industries. He transformed the business from a one-man-band with a station wagon operating out of the basement in his family’s home, to a fully equipped facility employing several technicians, churning out work for the “T”(Mass Bay Transit Authority), Hood milk, and many others.

In 1979, Joe followed his passion into auctioneering, and handed the business over to his younger brother Robert, who took on a partner, and incorporated the business as “Tech Hydraulics Inc.”. With the new heavy equipment and construction-oriented business brought in by the nearby Central Artery Construction Project-better known as the Big Dig-Robert moved the business to a larger facility nearby where the business is headquartered today. The Big Dig put hydraulic hammers into the hands of many contractors in the Boston area, and although the company had been repairing them since they became popular in the late 1970s, Robert saw them as a new growth opportunity in the late 1990s.

In 2003, Robert reached out to his brother Joe’s son, Joe Tedesco III. He proposed a new direction for the business, which would shift its focus towards hydraulic hammers, and use the trade name of “Gorilla” to set it apart with a more aggressive, more memorable moniker. Joe saw the potential, bought out Robert’s partner, and began working with Robert to transition away from cylinders, pumps, and valves into hydraulic breakers. The company invested in field service vehicles, state-of-the-art, specialized equipment and tooling to repair breakers, and added demolition tools and hammer parts to its inventory. Most importantly, honest, growth-oriented personnel were recruited who understood the urgency of customer service.

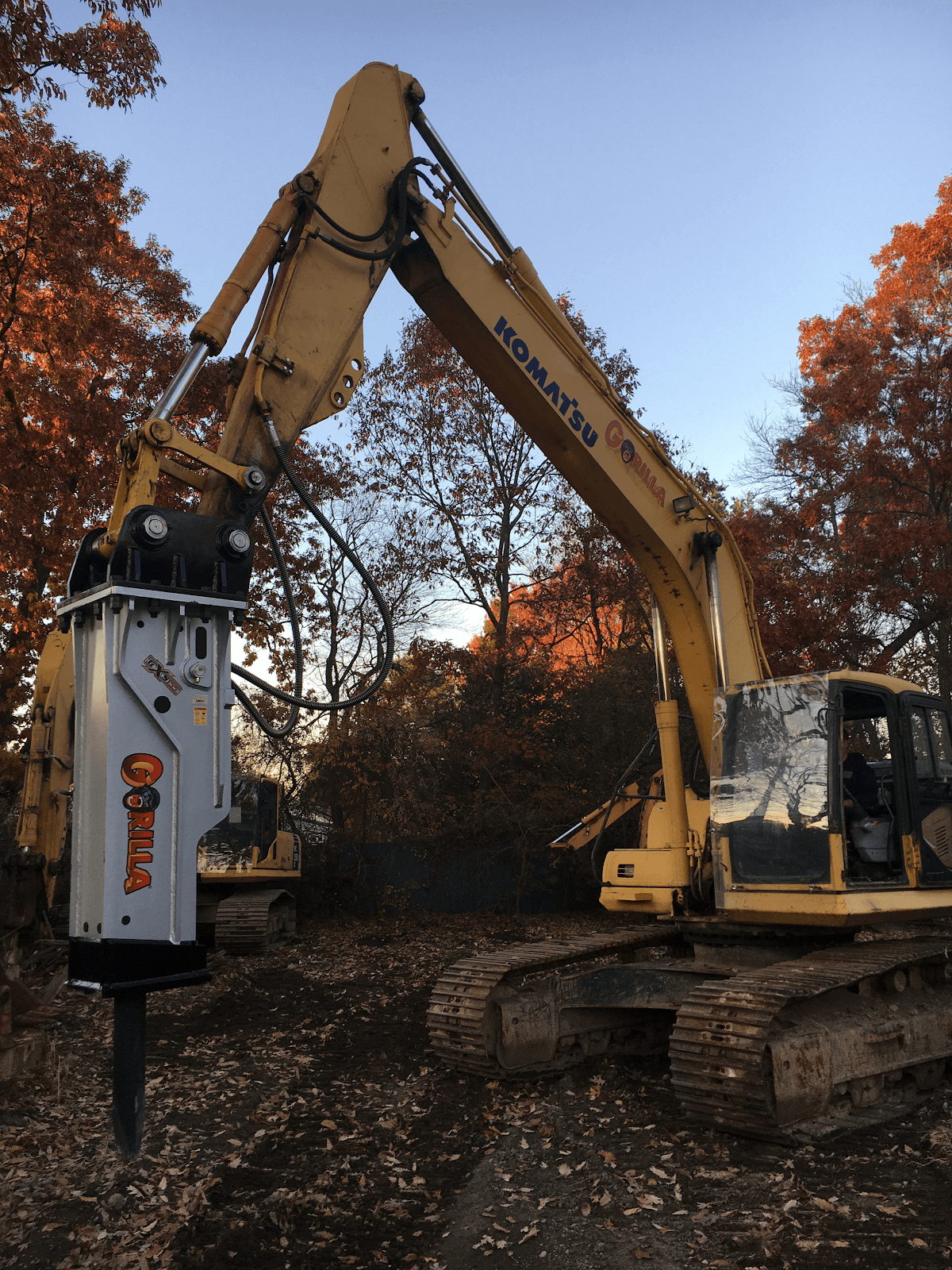

Within three years, the company doubled its revenues, and, with the help of the internet, began selling nationally as well as exporting to Canada, Mexico, and the Caribbean. By 2006, Gorilla had added its own rental fleet of hammer-equipped excavators. Based on what they learned from field testing in the unforgiving world of equipment rental and decades of repairing all other hydraulic breaker makes and models, the company adopted its own line of hydraulic hammers, known as the GHB line. Today, Gorilla now sports its improved GXS line, and over fifteen years and thousands of Gorilla Hydraulic Breakers later, the company continues to maintain a singular focus on hydraulic hammers, service, parts, and accessories, with the same level of customer service that the original Joe presented to his customers on his gas nozzle route over 80 years ago.

G. Stone Commercial Continues Growth With Doosan, Gorilla Lines

“To support the Doosan machines, G. Stone Commercial also has made the commitment to becoming a dealer for several attachment lines, including Craig, AMI, JRB and, most recently, Gorilla hydraulic hammers.

‘We are very excited about the commitment we just made to become Vermont’s Gorilla hammer authorized dealer,’ Darcy said. ‘We are very careful about what products we will represent. We have had a Gorilla 54,000-pound hammer in our rental fleet for over ten years and it has given us trouble-free performance, which is saying a lot when you consider New England’s hard rock conditions and a hammer that is going out to rental operators.’

We estimate that we have put at least 4,000 rental hours on that hammer. Of course, we do a very good job maintaining it — we go through it after every single rental, but it is still operating very strong.’

So, when Joe Tedesco, president of Gorilla Hammers, approached us about becoming their dealer, we were thrilled. It’s a brand that we can represent with a great deal of confidence. We have already experienced the great product and parts support available through Gorilla and with their support we will now be able to service and repair virtually all makes and models of hydraulic hammers. We can do that with a great deal of confidence knowing that the people at Gorilla are experts in their field who respond promptly and get it right the firsts time.'”

United Bros. Taps Solid Power of Gorilla Hydraulic Hammer

“Though he had used other hammers by various manufacturers over the years, David Dostie, president of United Bros., decided to try something different after reaching out to his dealer, Great Southern Equipment — a Gorilla hammer.

Bob Tedesco, owner of Gorilla Hammers, said United Bros. originally had its sights set a 14,000-lb. hammer, Gorilla’s largest, but after a look at the job site in the Jacksonville, Fla., area, he recommended something a little lighter.

Great Southern and Tedesco worked with Dostie to install a Gorilla GXS165 10,000-lb. hammer on a Kobelco SK480LC excavator. The process took just one day, and United was able to put the hammer to work that same afternoon.

‘With Bob coming in and meeting with us and telling us about his background in the hydraulics business and his expertise, I felt very comfortable that if I have a problem, they’re going to come fix it for me,’ Dostie said…

‘The bottom line is that we do everything we can to protect the hammer and are concerned primarily with how long we can make a hammer run,” Tedesco said. “I don’t want the fatalistic call that the hammer has gone down. What we do want to hear is that a customer needs a replacement tool bit.'”

Louisville Paving Pounds Rock With Gorilla Hammers

“Louisville Paving and Construction’s relationship with both Gorilla Hammers and Boyd and Sons Machinery goes back a long way.

Prior to Boyd and Sons Machinery being named the Gorilla dealer for Louisville, Brown had relied on the dealership as a source for undercarriage and hard-to-find parts that other vendors had difficulty providing.

In truth, Gorilla hammers are nothing new to Boyd and Sons Machinery. The company has been the authorized Gorilla dealer serving Indiana from its headquarters location in Washington, Ind., for more than seven years.

The contractor also has had extensive experience with Gorilla hammers. Louisville Paving and Construction’s first Gorilla was a GHB 150 hydraulic hammer that saw extremely heavy use for 10 years and that the company recently traded in for a new GXS165 10,000-lb. hydraulic hammer.

Brown explains the company was very happy with the GHB150’s performance, but after 10 years of hard work, it was just worn out.

Brown also went on to compare Gorilla hammers with others that Louisville Paving and Construction has owned or rented. In the course of its work, Brown states, the company constantly has to deal with the area’s limestone, which is notoriously hard and very unforgiving.

The company relies on hammers for work where it can’t blast or to break up stone to be hauled away after blasting. In these situations, it needs a hammer that will hold up. Recently, an operator using a different brand of hammer broke five bits in 3 ½ weeks. With its recently acquired Gorilla hammer, the same operator has been working for 2 ½ months with absolutely no issues.”