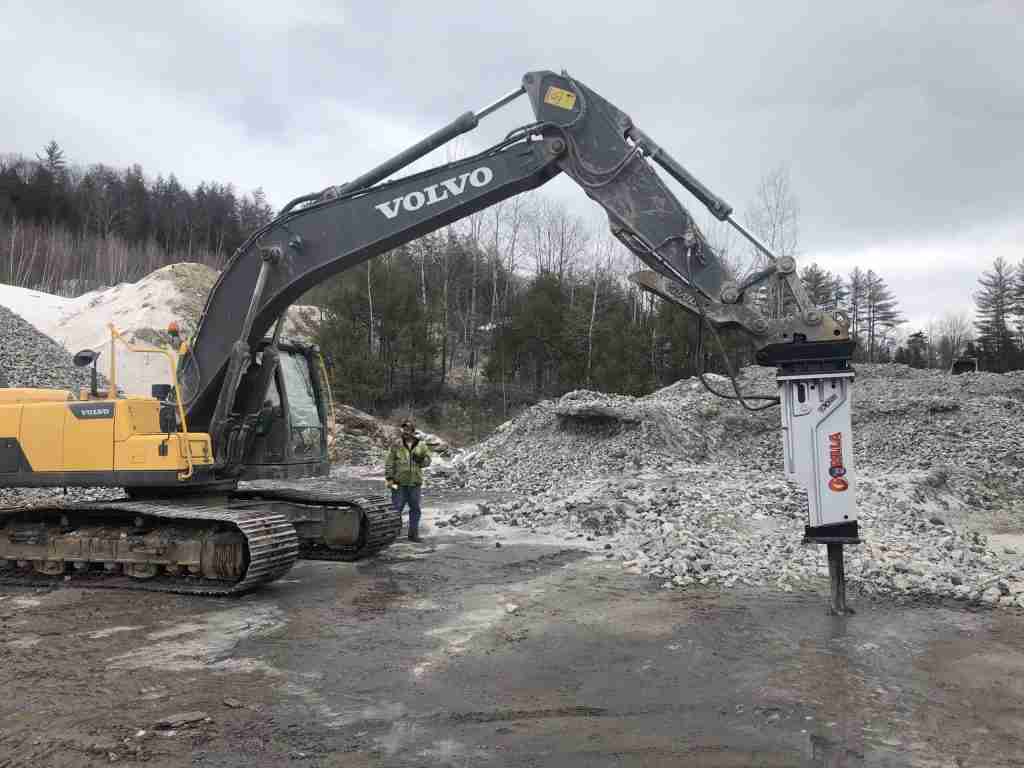

Top 3 Hydraulic Hammer Problems and How to Fix Them

Your hydraulic hammer attachment is one of the most expensive components of your hammer. Therefore, it must be kept in working order. If the hammer attachment isn’t working correctly, you will not be able to perform the job. Here are some of the most common hydraulic hammer issues to be aware of so that you […]

Top 3 Hydraulic Hammer Problems and How to Fix Them Read More »