Maintaining Your Gorilla Hammer: Essential Maintenance and Care Tips

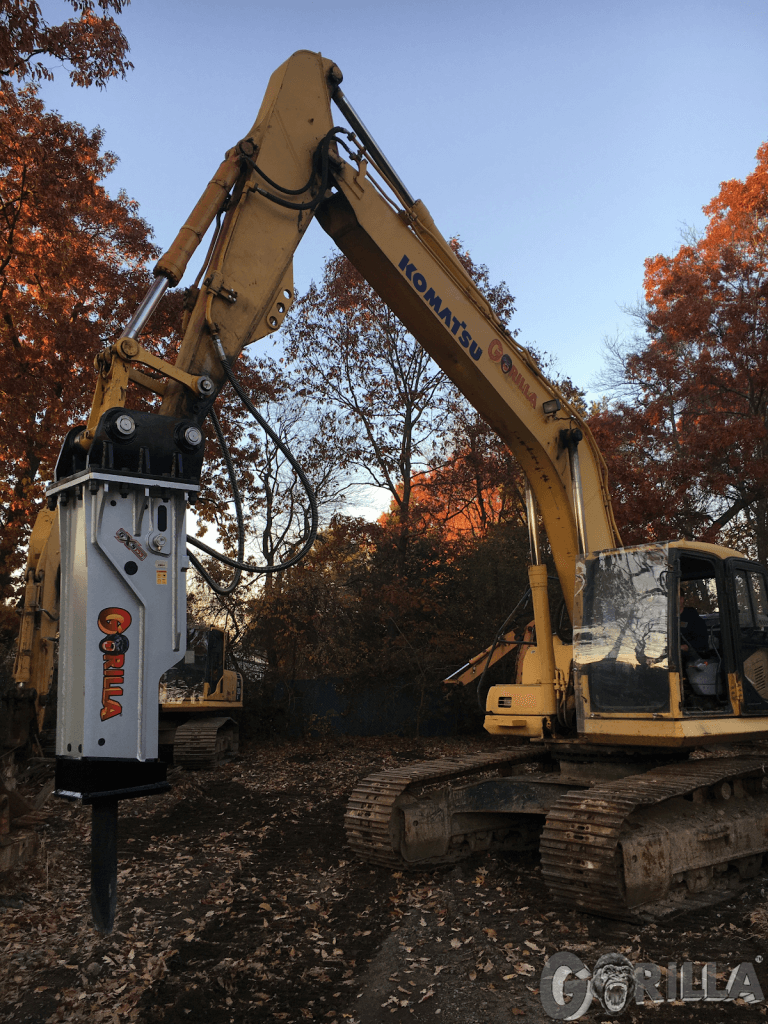

A Gorilla Hammer is a dependable and powerful tool that excels at heavy-duty construction and demolition tasks. Gorilla Hammers is a top maker of hydraulic hammers, breakers, and crushers in Randolph, Massachusetts. Their products are designed to survive extreme environments and function superbly. To maintain longevity and best performance, however, frequent maintenance and care are necessary, just like with any piece of machinery. We’ll give you some helpful advice in this post to help you maintain your Gorilla Hammer and keep it in great condition.

- Keep it clean: Take time to clean your Gorilla Hammer properly after each usage. Eliminate any accumulated dirt, trash, or concrete residue. To clean the exterior, use a soft brush or compressed air, and make sure that nothing is blocking any vents or cooling systems. Grime accumulation, which can cause corrosion and damage, is avoided by routine cleaning.

- Check for leaks: Gorilla Hammers’ hydraulic systems are vital to their performance. Check the hydraulic hoses and fittings frequently for any leaks that may be present, such as oil streaks or puddles. To prevent additional harm to the system, take urgent action if you discover any leaks.

- Lubrication is key: The smooth operation of your Gorilla Hammer requires proper lubrication. Follow the manufacturer’s instructions for applying lubricant to all moving parts, including pivot points and bushings. Utilize premium lubricants suggested for hydraulic machinery. Lubrication shortens the lifespan of your hammer, lowers wear and tear, and reduces friction.

- Inspect wear parts: Gorilla Hammers are built with a variety of utilized components, like chisels and bushings, that endure high amounts of stress while in use. Check for wear and tear on these components on a regular basis. To keep the hammer operating properly and avoid future damage, replace worn-out or damaged parts as soon as possible.

- Monitor operating pressures: Keep a close look at the Gorilla Hammer’s operating pressures. While insufficient pressure may lead to subpar performance, excessive pressure may tear interior components. To make sure the hammer is working within the suggested range, frequently check the pressure gauge and refer to the manufacturer’s instructions.

- Store it properly: When not in use, keep your Gorilla Hammer in a clean, dry location. Avoid exposing it to high temperatures, moisture, and direct sunlight because these conditions can cause its components to break down. Your hammer will last longer, and there will be less chance of damage with proper storage.

- Seek professional assistance: While routine upkeep can considerably increase your Gorilla Hammer’s effectiveness and durability, it is crucial to seek professional assistance when required. Consult a skilled expert who specializes in hydraulic hammers if you run into complicated problems or if you have questions regarding specific maintenance duties. They are qualified to accurately assess problems and offer workable solutions.

For more information, contact us today!

You can keep your Gorilla Hammer in top shape and get dependable and effective performance on the job site according to these important maintenance and care guidelines. Regular maintenance increases productivity and safety while also extending the life of your equipment. Your Gorilla Hammer will be a useful tool in your construction and demolition tasks for years to come if you put the time and effort into maintaining it. If you have any additional questions or would like to speak with one of our industry experts, please contact us at (888) 814-6745 or sa***@************rs.com right away.